Brrrrrr, today was a perfect, freezing Brisbane day, so it’s time to chat Cold Chain. Not super geeky, but I was out and around today, delivering beer and it got me thinking about how one of the most misunderstood quality parameters of beer is shelf-life.

Oxygen and beer are not friends. Whether it’s oxidised fatty acids that give a stale/cardboard flavour or oxidised hop compounds that lack the characteristic fresh grassy hop notes, in place of dull, candied flavours. And although beer goes from one pressure vessel to another, there is always a level of oxygen that infiltrates the beer; from raw material storage, to dry hopping, to tank cleaning, to putting beer in a can or keg.

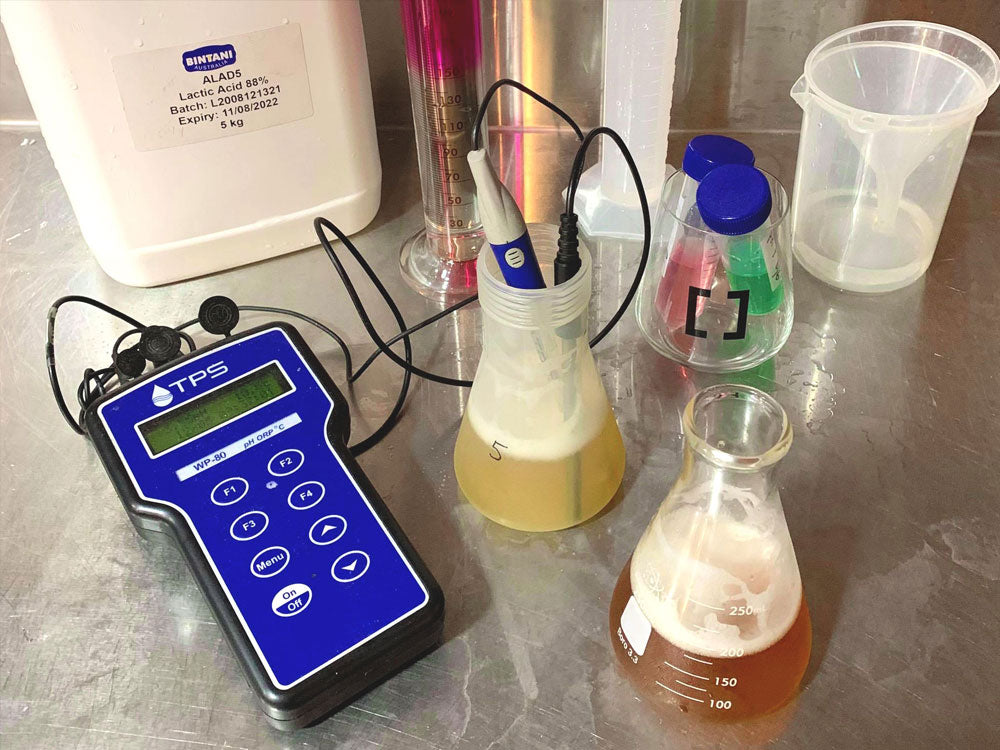

Even the best brewers with the best equipment make beer that suffers from oxygen ingress. It’s all a matter of concentration. To measure oxygen concentration we use a “dissolved oxygen meter”. We are lucky enough to have access to an Anton Paar Cbox, a very accurate dO2 meter.

Our brewing equipment is by no means first class, and our brewer is certainly pretty suss, so our dO2 levels are pretty average, to be honest. We are looking like 20-40 parts per billion (ppb) from fermenter to brite tank and 50-200 ppb on canning. We have done a lot to improve this process, especially around dry hopping and canning to alleviate this load. A gold standard is to keep the sum of all dO2 well below 50 ppb throughout the entire process.

With this in mind, we put a 6 month best before date on all our products. And our business model is concrete on keeping batches small and selling out well before this date. Also, lucky for us, and you guys, we have some cold room space for storage. All our beer goes from the brewery to cold room the very day of packaging, nothing is left warm. All interstate deliveries are transported refrigerated. You see the higher the temperature the quicker the oxidation reaction. So by keeping the beer cold, the small amount of oxygen in the final product reacts much slower, making the beer tastier for longer.

Think of it like this, good beer is like milk. It’s a living product and goes off in a matter of weeks. Check the BBF and get educated.

Keep it small, keep it cold, keep it fresh!